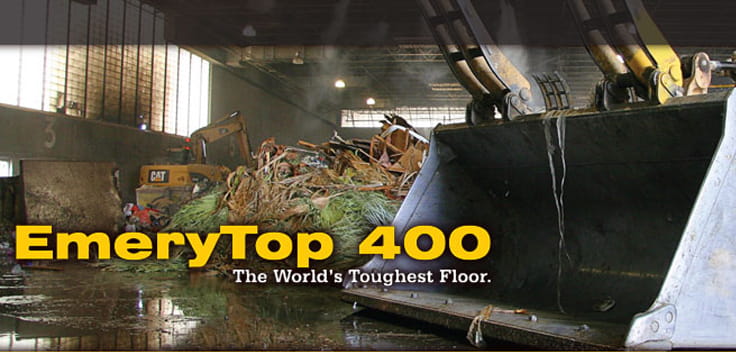

Multiply The Service Life of your Transfer Station Tipping Floors with the World’s Toughest Concrete Topping.

No other type of concrete floor needs the degree of abrasion resistance, impact resistance, or chemical resistance as your transfer station tipping floor or heavy-traffic industrial floor.

L&M™ EMERYTOP 400™ floors are the toughest floors in the world. This isn't hype. It's a fact, and we can prove it. EMERYTOP 400 was developed for the solid waste industry's transfer station tipping floors.

EMERYTOP 400 is also the best choice for any floor subject to high point loads, high impacting loads and high abrasion. It's an excellent choice for floors subject to heavy machinery with cleats of pan type track. The non-metallic, non-rusting topping is effective indoors and outdoors.

Why do Other Toppings Fail?

Other toppings address only impacting loads and abrasion. They don't address one of the most important causes of early topping failure: Chemical Attack.

EMERYTOP 400 is chemically engineered to combat common chemicals that destroy the cement paste holding the aggregate in place. These include milk, vinegar, urine, animal fat and most household chemicals--all common in solid waste. Once the cement paste is destroyed, the aggregate is lost.

It can be placed over existing concrete floors or freshly placed concrete. The average thickness of placement is between ¾ inch and one inch (or more if required).

Why are EMERYTOP 400 Floors so Tough?

These floors have twice the abrasion resistance of iron toppings and other emery toppings. Emery aggregate is the toughest aggregate is the world with a mohs hardness of 9. (A diamond has a mohs hardness of 10.)

Most metallic aggregates have a mohs hardness of about 7 to 7 ½.

The major difference between EMERYTOP 400 and other toppings is how it is chemically engineered to resist chemical attack.

EMERYTOP 400 chemically reinforces the cement paste against chemical attack, which doubles the abrasion resistance when compared to other emery toppings and iron toppings. This synergy between the emery aggregate and the chemically resistant cement paste that gives EMERYTOP 400 its very high abrasion resistance.

Why EMERYTOP 400 and Not Other Toppings?

- Greater Abrasion Resistance

- High Energy-Absorbing Capacity for Improved Impact Resistance

- Non-Rusting

- Greater Increased Resistance to Chloride Ion Penetration

- Modulus of Elasticity Very Similar to Concrete for Greater Compatibility

- Lower Drying Shrinkage Assuring Good Bond to Substrate

- Can Be Placed and Finished Like Flowing Concrete

- Lower Life Cycle Cost

How Can I Have an EMERYTOP 400 Floor Installed?

LATICRETE has trained a number of concrete contractors in the proper procedure for placement of EMERYTOP 400. These skilled crews can schedule the work in a manner that will have the lowest impact on your operation, and will give you a turnkey price. Should you want to use your own concrete contractors, at no cost LATICRETE will have a factory-trained expert at the job site the day of the placement of the EMERYTOP 400.

Multiply the service life of your transfer station tipping floors with the world’s toughest concrete topping: Designed specifically for the solid waste industry.